Food and beverage manufacturers have to adhere to extremely high standards of production quality, both to meet their regulatory obligations and to manage risk when bringing a product to market. Sieving and sifting food powders is a critical step in the manufacturing of several products, one that is responsible for filtering out fine impurities that can affect overall quality. As a result, your choice of a vibratory sifter and media will play an important role in the overall productivity, cost-effectiveness and long-term viability of your organization. Here’s what you need to know to make an informed decision.

Not All Vibratory Sifters Are the Same

Vibratory sifters/screeners can generally be classed into one of three types:

- Circular screeners that gently separate fine materials using a vibratory motion. Circular screeners are typically more sophisticated screening machines that are suitable for use with delicate product. They have a smaller footprint, but often do not process materials as quickly.

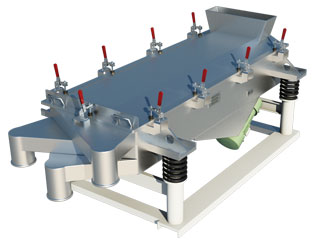

- Rectangular screeners can quickly sift and sort high volumes of material. They offer greater flexibility in terms of material size and separation. However, they have a larger footprint and are not as refined as their circular counterparts.

- Mechanical separators are simpler machines that are less costly to purchase and operate. They can quickly screen bulk materials but typically are not capable of the fine processing required for sifting food powders.

The first step in choosing the right sifter for sieving food powders is to know which type of machine is required. If you’re unsure, speak with a VibraScreener™ representative for assistance in narrowing down your choices.

Knowing Your Regulatory Requirements

The main factor that differentiates food powder sieving from other industrial processes is the need for increased hygiene. Depending on the nature of your operation, you may be required to comply with Hazard Analysis Critical Control Point (HACCP) food safety management requirements, 3-A sanitary standards, FDA and USDA regulations, and more. Meeting these challenges requires purpose-built equipment that will deliver accuracy and sanitary performance in clean operating environments.

Making Safety a Priority

Aside from your regulatory requirements, an industrial food powder sifter must be safe for your employees to use. Dust created by sifting machines is an irritant and may pose an explosive hazard. Any vibratory sifter used for processing food or beverage powders should be equipped with an appropriate ventilation hood to prevent accidents and illness.

Respecting Your Bottom Line

In a competitive industry such as food manufacturing, your equipment and your processes must work together to deliver efficiency and accuracy on the job. The right sifter will provide reliable performance at a low operating cost. Choose a machine that’s easy to maintain and made from high quality components, such as the VibraScreener™ SaniDump Screener™. One of our most effective products for food powder sieving, the SaniDump Screener™ is powerful, precise, safe and sanitary.

For more information about the SaniDump Screener™, or about other VibraScreener™ products suitable for food and beverage processing, contact a representative today.