Metal powders—used in additive manufacturing, metallurgy, and coatings—demand unwavering precision in classification to ensure uniformity, purity, and performance. Even slight variations in particle size can lead to defects in 3D-printed parts, inconsistent coatings, or inefficient sintering. Traditional screening struggles here, often blinded by fine, abrasive particles that stick to meshes, causing inconsistent separations and high waste. Ultrasonic sieves, with their high-frequency deblinding technology, emerge as indispensable tools, revolutionizing how manufacturers handle these challenging materials. At VibraScreener™, our ultrasonic solutions are purpose-built for metal powder applications, delivering micron-accurate grading that elevates product reliability and process economics.

Tackling the Unique Challenges of Metal Powders

Metal powders, such as aluminum, titanium, or stainless steel variants, are typically ultra-fine (down to 10 microns) and prone to electrostatic charging or oxidation, exacerbating clumping. Conventional vibratory sieves falter under this, with throughput dropping as meshes clog within minutes. Ultrasonic sieves counteract this by emitting 35 kHz pulses that create a cavitation effect, fluidizing particles and keeping screens clear. This ensures continuous, high-fidelity classification—separating oversize from fines without compromising flow rates. In powder metallurgy, this translates to tighter size distributions, reducing voids in compacted parts and improving mechanical properties.

Precision Grading for Superior Material Performance

Classification isn’t just about size; it’s about achieving the exact morphology needed for downstream processes. Ultrasonic technology provides gentle, uniform energy that avoids particle attrition or shape distortion, preserving spherical integrity crucial for applications like thermal spraying. For instance, in aerospace-grade titanium powders, our sieves achieve 99%+ purity levels, minimizing impurities that could weaken components. This precision also aids in recycling metal scraps, where ultrasonic sieving recovers high-value fines efficiently, supporting sustainable practices without quality loss.

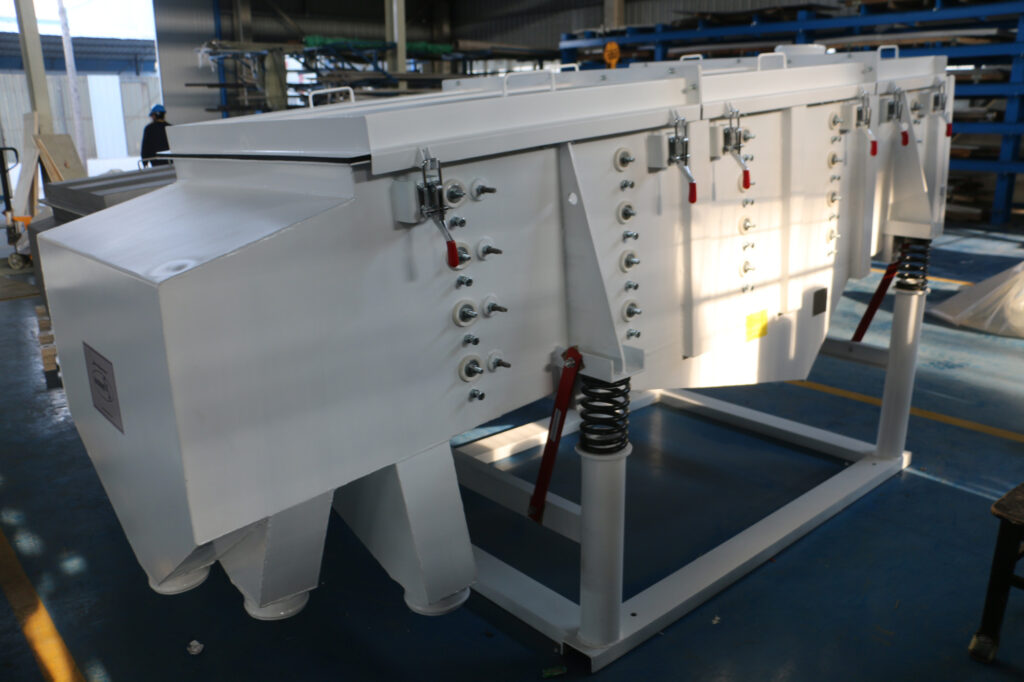

Ensuring Compliance and Operational Resilience

Metal powder handling involves stringent standards, from ISO certifications to REACH regulations, demanding contamination-free processes. Ultrasonic sieves feature electropolished stainless-steel frames and tool-free assemblies, facilitating rapid sanitization and preventing cross-alloy contamination. Their enclosed designs further curb dust emissions, enhancing workplace safety in line with OSHA guidelines. Operationally, these sieves boast uptime rates over 95%, thanks to self-cleaning meshes that extend service intervals. In high-stakes environments like automotive forging, this reliability means fewer production halts and faster ROI.

Boosting Efficiency in Metal Processing Workflows

Beyond accuracy, ultrasonic sieves optimize the entire classification pipeline. Integrated with multi-deck configurations, they enable simultaneous separations into multiple fractions, accelerating R&D prototyping or batch production. Energy consumption remains low, with ultrasonic transducers drawing minimal power while delivering outsized gains—often 3x the capacity of standard sieves for sub-50 micron cuts. Metal fabricators using our equipment report 25-40% reductions in scrap rates, directly padding profit margins.

To see this in action, visit our ultrasonic vibrating sieve for fine powder screening, featuring specs optimized for metal powders and real-world case studies.

Final Thoughts: The Edge in Metal Powder Innovation

In an industry where precision defines success, ultrasonic sieves aren’t optional—they’re critical for staying competitive. VibraScreener™ empowers metal processors with robust, adaptable technology that turns classification challenges into strategic advantages, fostering innovation from lab to factory floor.

Eager to classify with confidence? Connect with VibraScreener™ experts today for a custom assessment or free sample screening. Let’s refine your metal powder process to perfection.