Sieving is the backbone of material processing across industries, from pharmaceuticals to chemicals and beyond, ensuring particles are separated, graded, and purified to exact specifications. But with options ranging from basic vibratory screens to high-tech ultrasonic systems, how do you decide? Traditional sieving relies on mechanical vibration to move materials over mesh surfaces, a proven method for decades. Ultrasonic sieving, however, introduces high-frequency sound waves to enhance this process, tackling limitations that plague conventional setups. At VibraScreener™, we’ve engineered both types to meet diverse needs, helping operations choose based on throughput, material type, and compliance demands. This comparison breaks down the pros, cons, and ideal scenarios for each.

Core Mechanisms: Vibration vs. Augmented Precision

Traditional sieving uses eccentric weights or electromagnetic drives to generate rhythmic oscillations, effectively stratifying particles by size. It’s straightforward, cost-effective for coarse materials, and handles moderate volumes well—think aggregates in mining or basic powder de-dusting in food. However, with fine or sticky powders, it often leads to mesh blinding, where particles adhere to screens, slashing efficiency by up to 50%.

Ultrasonic sieving builds on this foundation by overlaying 20-40 kHz ultrasonic vibrations. These micro-pulses create a “floating” effect on the mesh, repelling particles and preventing buildup. The outcome? Dramatically improved flow for sub-micron separations, ideal for high-value applications like pharmaceutical actives or cosmetic pigments. While traditional methods excel in simplicity, ultrasonic tech shines in precision, often boosting accuracy by 90% or more.

Performance and Throughput Considerations

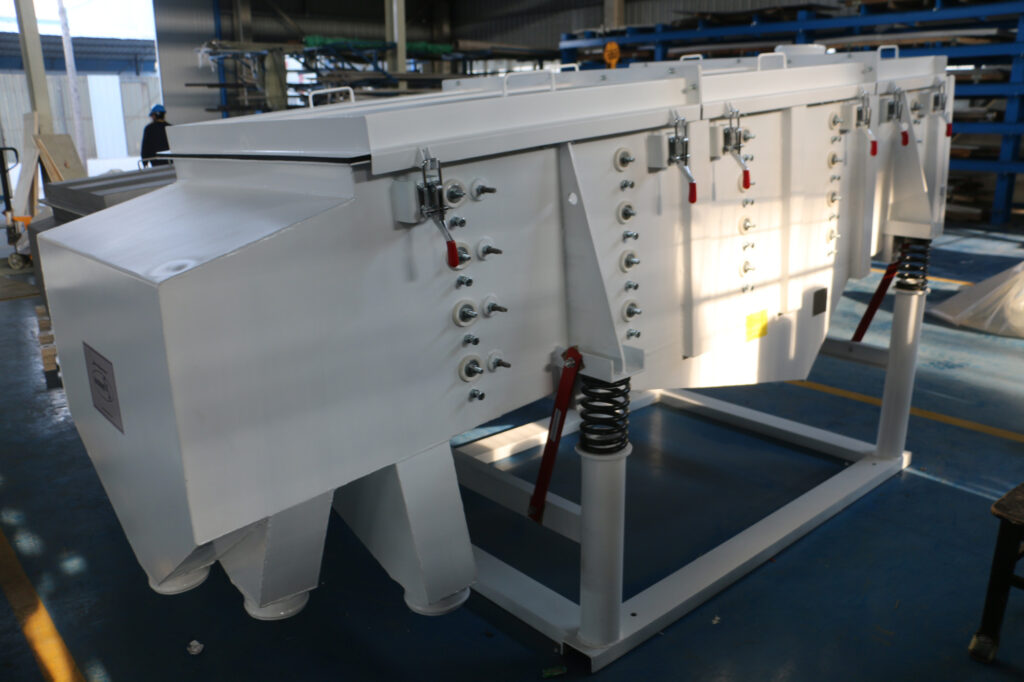

For operations prioritizing volume over finesse, traditional sieves win on affordability and robustness. They process bulk solids like grains or chemicals at rates exceeding 10 tons per hour, with minimal energy draw. Yet, frequent clogs demand manual intervention, inflating labor and downtime costs—sometimes 2-3 times higher than automated alternatives.

Ultrasonic systems flip the script for fine-particle challenges. In scenarios with cohesive powders, they deliver 2-5 times the throughput of traditional sieves by maintaining open apertures. Energy use is comparable, but the real savings come from reduced waste and rework. For scaling businesses, this means fewer bottlenecks during peak production, ensuring consistent output without oversized machinery.

Maintenance, Compliance, and Cost Factors

Ease of upkeep varies: Traditional sieves require regular tapping or brushing to clear meshes, which can introduce contamination risks in sanitary environments. Ultrasonic models minimize contact, featuring hygienic designs that speed cleaning—often under 10 minutes—and extend mesh life by 300%. This is crucial for FDA-regulated sectors, where ultrasonics’ non-abrasive action supports cGMP standards effortlessly.

Upfront, traditional sieves are budget-friendly (starting at $5,000), suiting small-scale ops. Ultrasonic setups command a premium ($15,000+), but ROI materializes quickly through efficiency gains—typically within 6-12 months via lower operational expenses.

When to Choose Each: Tailored Recommendations?

Opt for traditional if your materials are coarse, dry, and high-volume, like in recycling or basic mineral processing. It’s reliable for straightforward tasks without the bells and whistles.

Choose ultrasonic for fine, sticky, or high-precision needs—pharma powders, food additives, or metal classifications—where quality trumps cost. Hybrid options, like our Ranger Separator™ with ultrasonic add-ons, bridge the gap for versatile lines.

For a closer look at ultrasonic capabilities, check out our ultrasonic vibrating sieve for fine powder screening, complete with performance data and customization details.

Final Thoughts: The Right Fit for Peak Performance

Neither sieving method is universally superior; success hinges on aligning technology with your process realities. At VibraScreener™, we guide clients through testing and selection to match equipment that amplifies strengths and mitigates weaknesses, fostering long-term efficiency.

Curious which suits your operation? Reach out to VibraScreener™ for a no-obligation material test or quote. Let’s sieve out the guesswork and optimize your workflow today.