In industries that handle fine powders—such as pharmaceuticals, chemicals, and food processing—ensuring particle uniformity and purity is essential. Even minor inconsistencies in particle size can compromise product quality, affect performance, and create compliance challenges. At VibraScreener™, we recognize the critical role that ultrasonic sieve technology plays in achieving precise screening and consistent results.

Eliminating Particle Blockages and Improving Accuracy

Traditional sieving methods can struggle with fine or cohesive powders that tend to clump or bridge, reducing throughput and accuracy. Ultrasonic sieves use high-frequency vibrations that transmit through the mesh, preventing clogging and promoting continuous particle flow. This ensures that only the correctly sized particles pass through, minimizing waste and rework.

Protecting Material Integrity

Fine powders are often sensitive to heat, moisture, or mechanical stress. Ultrasonic sieves apply gentle, yet effective, vibrations that prevent particle breakage while maintaining material characteristics. This is particularly important for delicate pharmaceutical ingredients, high-value chemical powders, or flavor-sensitive food ingredients, where maintaining quality and functionality is non-negotiable.

Supporting Regulatory Compliance

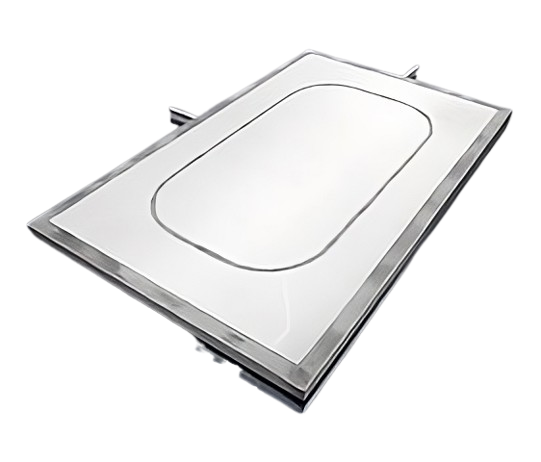

Industries handling fine powders must adhere to strict safety and sanitation standards, such as FDA, cGMP, or 3-A sanitary regulations. Ultrasonic sieves are designed with hygienic construction, stainless-steel surfaces, and easy-to-clean components. By reducing powder accumulation on mesh screens and equipment surfaces, these sieves help facilities meet compliance requirements while minimizing downtime during cleaning or material changeovers.

Enhancing Operational Efficiency

Beyond accuracy and compliance, ultrasonic sieves boost overall productivity. By reducing clogging and downtime, these machines allow for higher throughput and smoother material flow. This translates to lower labor costs, reduced material loss, and a more reliable production process. Manufacturers can scale production with confidence, knowing that screening precision will remain consistent across batches.

Tailored Solutions for Fine Powder Applications

VibraScreener™ offers ultrasonic sieves designed to meet diverse industry needs. Whether processing pharmaceutical powders, chemical granules, or food ingredients, our equipment can be customized for mesh size, capacity, and vibration frequency. Each solution is built to ensure maximum efficiency, consistent particle quality, and compliance with industry standards.

Optimizing Powder Processing with Ultrasonic Sieves

Ultrasonic sieves are a transformative solution for fine powder handling, combining precision, efficiency, and material protection in one technology. To explore how VibraScreener™ can improve your screening process, contact us today to discuss your requirements and get a personalized recommendation for the right ultrasonic sieve solution.