Ultrasonic Sieve

Ultrasonic Sieve

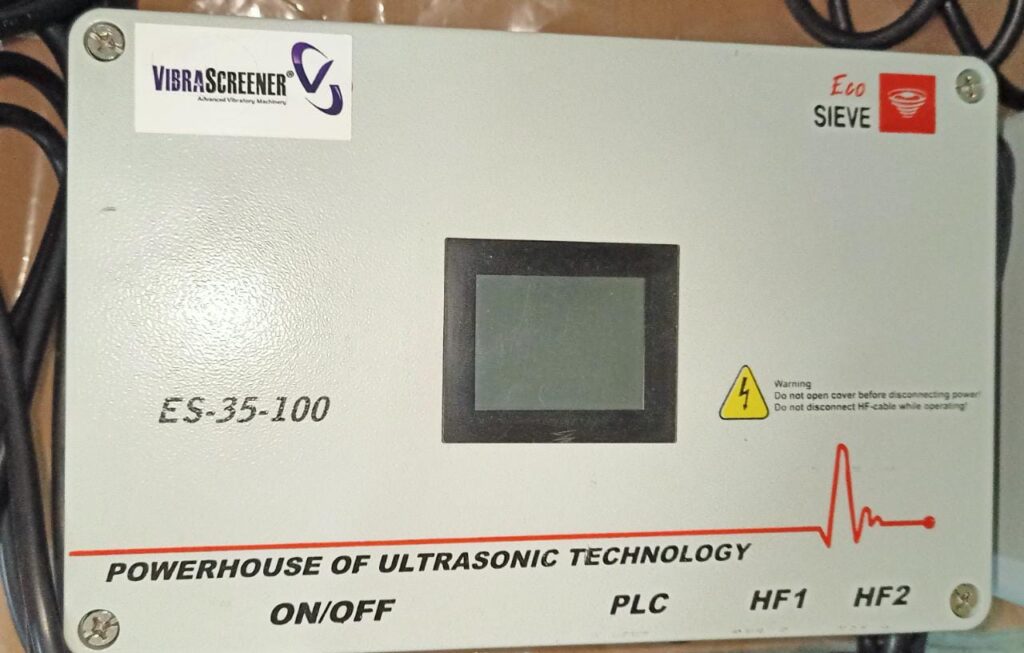

VBS ULTRASCREEN Ultrasonic Sieve Systems for Superior Powder Screening

Why choose the VBS ULTRASCREEN Ultrasonic Sieve?

The VBS ULTRASCREEN ultrasonic sieve is an advanced sieving solution that uses ultrasonic frequencies to enhance separation accuracy and flowability. Unlike traditional screeners that rely solely on mechanical vibration, the VBS ULTRASCREEN system uses oscillating waves transmitted through ring resonators to the mesh surface. These vibrations help break down agglomerates, prevent clogging, and ensure maximum product purity.

This system can be integrated into existing vibratory screeners or sifters, transforming them into high-efficiency ultrasonic sieving machines that meet stringent quality and safety standards.

Key Features of the VBS Ultrasonic Sieve Shaker Technology

- Consistent Vibration Across Larger Frames

Our custom ring resonators ensure even mechanical oscillation, even on large-diameter screens, up to 1600 mm.

- No Blockages, No Downtime

Eliminate screen mesh blinding with precision ultrasonic pulses. Maintain a clean, free-flowing sieve for all powder types.

- Increased Yield and Quality

Enjoy better product selectivity, reduced oversized particles, and up to 30% higher throughput, even when using finer mesh sizes.

- Supports Wet & Dry Screening

Our ultrasonic vibro sifters are ideal for both dry powders and wet slurry screening applications.

- Extended Mesh Life

With lower mechanical stress and uniform vibration, the service life of your sieve mesh is significantly extended.

- Low Maintenance and Energy-Efficient

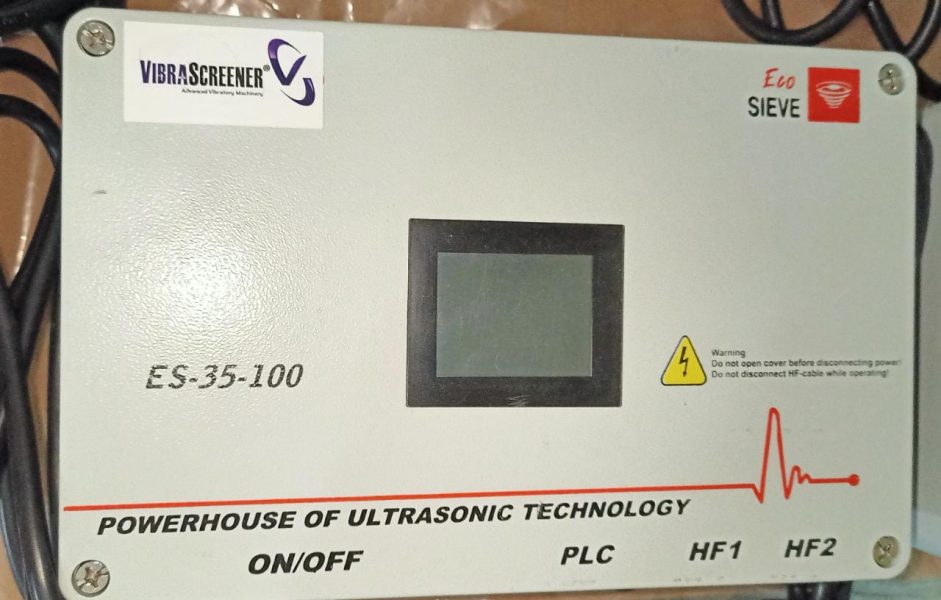

With adjustable energy inputs, PLC interface, and PC control, our systems offer flexibility and reduced operating costs.

Benefits of Using Our Ultrasonic Sieving Machine

- Fast ROI with best-in-class price-to-performance ratio

- Explosion-proof and waterproof design for safer operation

- ATEX-certified and built for demanding industrial environments

- Customizable settings with 8 operating intensities to match your material needs

- Retrofittable to all standard vibratory or wobble screening machines

- No mechanical deblinding devices needed reducing contamination risk

- Ideal for fine and specialty powders such as acrylics, PE/PU, hybrid coatings, waxes, ceramics, and food additives

Applications for the VBS Ultrasonic Vibro Sifter Systems

Our ultrasonic sieve shakers are widely used across various industries, including:

- Pharmaceuticals – for precise particle sizing of active ingredients

- Powder Coatings – including acrylic and hybrid powders

- Metal Powders – such as titanium, aluminum, and other fine particulates

- Ceramics – for uniform particle size in clay and glaze powders

- Food Additives – safe and contamination-free screening

- Chemicals – reducing agglomeration and improving product flow

Whether you’re scaling up production or optimizing an existing line, our ultrasonic solutions offer unmatched control and reliability.

Enhance Your Screening Process with Vibrascreener’s Ultrasonic Sieve Cleaner

Upgrade your equipment with our ultrasonic sieve cleaner attachments for effortless cleaning and maintenance. This integrated deblinding system not only maintains optimal throughput but also significantly reduces labor, energy, and screen replacement costs. Say goodbye to traditional cleaning cycles and welcome a smarter, cleaner, and more efficient process.

Ready to Retrofit or Install New?

Client Testimonials