Cyclone Screener™

Cyclone Screener™

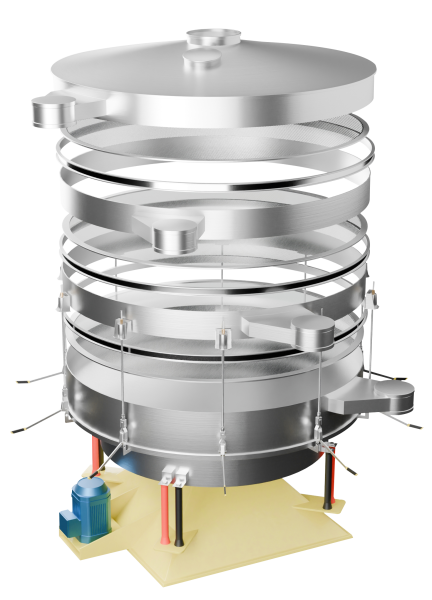

The Cyclone Tumbler Screener™ is a high-efficiency circular tumbler screening machine, designed for large capacity and difficult industrial screening applications where high capacity and precision screening are required. This high-performance tumbler sieving machine is highly used in screening/grading applications in numerous industries, such as plastic pellet screening, food ingredients, metallurgy, ceramic powders, chemical powders, fertilizers, agriculture, minerals screening, and many others.

This advanced gyratory tumbler screening equipment incorporates a side-to-side gyratory motion in a round robust tumbler design that makes this tumbler sieving machinery unique for high precision. The Cyclone Tumbler Screener™ features gyratory counterweight system on the base of this tumbler screening separator and not on the motor, this allows this tumbler sieve machine to generate a much higher amplitude making it more efficient than most conventional tumbler screening machines.

Advantages of the Cyclone Tumbler Screener™

Trust the Cyclone Tumbler Screener™ for your Most Challenging Screening Jobs!

- Fine Screening

The gyratory tumbling design of the Cyclone Screener allows for much finer screening as the material stays longer on the screen and enables the material that is near the same size as the mesh aperture more opportunity to pass the screen. This unit also gives operators the flexibility to use different de-blinding methods, including bouncing balls de-blinding, brush cleaning, air cleaning, ultrasonic screening, and a combination of all these methods. For additional efficiency, operators can also choose ultrasonic replacement screens to minimize blinding and downtime.

- Higher capacity

The main reason the Cyclone Tumbler Screener provides greater capacity than conventional vibratory screeners is due mostly to the high-speed stationary motor. Not having counterweighs on the motor enables the unit to utilize a higher speed motor. Another reason this round gyratory sieve separator produces greater capacity is because of its rubber mounts, which allows a stronger motor to be utilize. With this gyratory technology a more stable and controlled motion is obtain, allowing more materials to pass the screen easily and faster.

- Precise screening / separation

The Cyclone Screener™ with its advanced tumbler design is extremely effective when accurate separation is required. The unit was developed to combine accurate screening with high capacity in a compact round design. This tumbler screener allows the material to move on the screen side to side forcing the product longer time on the screen and giving more chances to pass the mesh screen.

- Rubber Suspension – balanced vibration

The Cyclone Screener is equipped with rubber mounts giving the sieve a more stable vibration, perfectly isolating vibration to transmit outside the base of the machine. This Contrary to metal springs in conventional round separators, the rubber suspensions allow more force to be applied directly to the screen surface and higher sieving capacity is achievable.

- Lower noise level

Without a vibratory motor and with rubber isolations, the Cyclone Tumbler Screener operates quietly with less moving parts. With the gyratory gentle motion of the Cyclone Screener the moving parts dance side to side and not up and down as vibratory screeners.

- Small footprint

Despite its superior design this tumbler sieving machine differentiates from rectangular gyratory screening machines counterparts because of its circular design and small footprint. The sieve uses a pedestal base, where the counterweights are located, and is compact and does not require excessive headroom in the installation and process. This base also makes the Cyclone Screener™ low maintenance as it provides quick access to the weights.