In the fast-paced world of food processing, where every minute counts toward meeting consumer demands for high-quality, contaminant-free products, efficiency is more than a buzzword—it’s a necessity. From milling grains to sifting spices and powders, the food industry relies on precise separation to maintain flavor integrity, nutritional value, and regulatory compliance. Traditional screening methods often fall short, leading to clogs, inconsistent particle sizes, and costly downtime. Enter ultrasonic sifters: innovative solutions that apply high-frequency vibrations to prevent mesh blinding and ensure seamless material flow. At VibraScreener™, our advanced screening equipment is engineered to tackle these challenges head-on, empowering food manufacturers to boost output without compromising on standards.

Overcoming Common Food Processing Hurdles

Food ingredients like flour, sugar, cocoa, and dairy powders are notoriously prone to agglomeration due to moisture, oils, or static electricity. This results in reduced throughput and uneven grading, which can affect product texture and shelf life. Ultrasonic sifters address this by generating ultrasonic waves that fluidize particles on the screen surface, dislodging them from mesh apertures instantly. The result? Up to 400% higher throughput compared to conventional vibratory screeners, allowing lines to run longer and produce more batches per shift. For instance, in bakery operations, this means finer, more uniform flour sifting, leading to consistent dough handling and baked goods that meet exact specifications.

Enhancing Product Quality and Safety

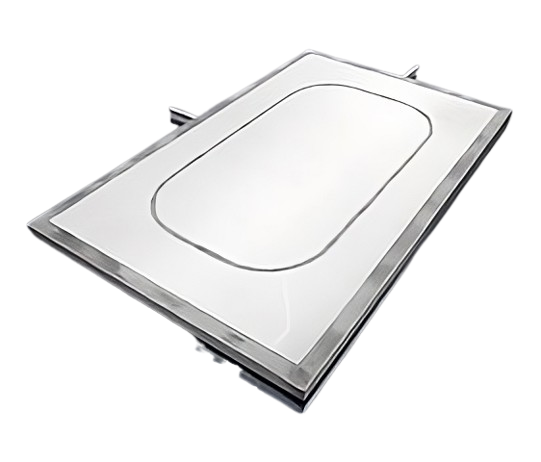

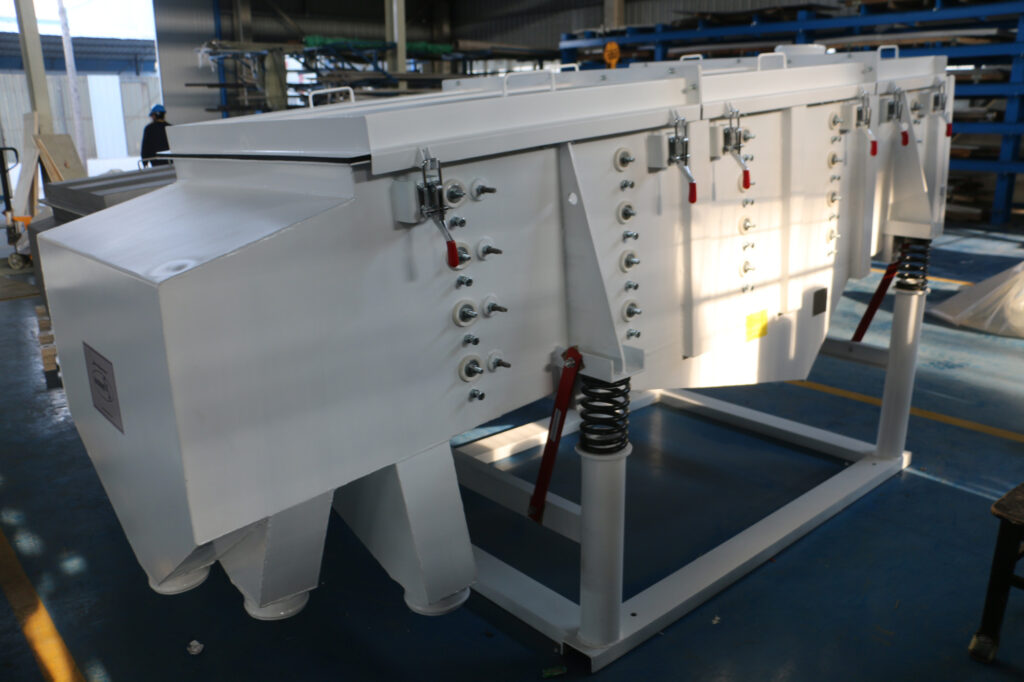

Quality control in food production isn’t just about taste—it’s about safety. Contaminants like insects, fibers, or foreign debris must be removed to prevent recalls and health risks. Our ultrasonic technology excels here, providing micron-level precision for even the finest powders, ensuring only pure material advances to packaging. This precision is vital for allergen management, where cross-contamination could spell disaster. Moreover, the gentle vibration profile preserves delicate ingredients, such as herbs or protein isolates, without generating excess heat that could degrade nutrients or alter flavors. By integrating features like quick-release clamps and stainless-steel construction, VibraScreener™ sifters align seamlessly with FDA and USDA guidelines, simplifying audits and inspections.

Streamlining Operations for Scalability

Scalability is key as food brands expand to meet global markets. Ultrasonic sifters are designed for versatility, handling everything from low-volume artisan runs to high-capacity industrial lines. Their compact footprint fits into existing setups, minimizing retrofitting costs, while energy-efficient motors reduce utility bills—often by 20-30% over traditional models. Maintenance is a breeze too: with fewer moving parts and self-cleaning ultrasonic action, downtime drops dramatically. Food processors report faster changeovers between products, enabling agile responses to seasonal demands, like ramping up spice production for holiday peaks.

Real-World Impact in Food Applications

Consider a dairy processor using our equipment to sift whey protein concentrate. Previously plagued by screen blinding, they achieved a 150% productivity surge, cutting waste and improving yield. Similarly, in nut butter manufacturing, ultrasonic sifting removes grit and shells efficiently, yielding smoother spreads that delight consumers. These success stories underscore how our solutions transform bottlenecks into bottlenecks no more.

To dive deeper into this technology, explore our ultrasonic vibrating sieve for fine powder screening, where you’ll find detailed specs tailored to the food industry’s needs.

Final Thoughts: Elevate Your Food Processing Game

Investing in ultrasonic sifters isn’t just about equipment—it’s about future-proofing your operation against rising costs and stricter regulations. At VibraScreener™, we blend decades of expertise with cutting-edge innovation to deliver sifters that drive real results: higher yields, superior quality, and happier teams.

Ready to supercharge your food production? Contact VibraScreener™ today for a free consultation or on-site demo. Let’s sift through the challenges together and uncover the productivity potential in your process.