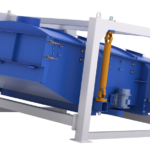

The GyraSift™ gyratory sifter is an advanced industrial screener separator and high-performance gyratory industrial screening machine generating a gyratory vibration motion close to level plane at low angles in a reciprocating side to side motion. This unique industrial gyratory sifter was designed to provide a cleaner cut of materials while still allowing higher screening capacity.

The GyraSift™ gyratory sifter/screener is the ideal industrial screening machine for dry applications where a cleaner separation is necessary, providing higher screening capacity and a much cleaner product. The GyraSift™ is also the perfect industrial screening equipment for sifting and screening materials with variables shapes, due to its gyratory, side to side sifting motion. This gyratory screener also offers numerous advantages over traditional rectangular screening equipment, making the GyraSift™ the most advanced and easy-to-own industrial sifter.

Benefits of the GyraSift™ – Gyratory Sifters / Screeners

Su elección de una criba vibratoria rectangular tendrá un efecto a largo plazo en su productividad, su rentabilidad y el futuro de su negocio. ¿Qué hace que el tamiz GyraSift ™ sea diferente de otros tamices rectangulares industriales? Como todos los productos VibraScreener ™, construimos la pantalla GyraSift ™ desde cero para ofrecer un rendimiento superior en cualquier aplicación. Elíjalo cuando necesite una criba vibratoria que le proporcione:

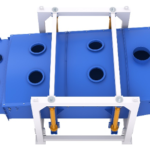

Design of the Gyrasift™ — Gyratory Sifter Equipment and Screeners

Our team engineered the Gyrasift™ with several distinctive features to deliver a solution that meets the needs of industries sifting dry materials, such as fertilizer and other bulk solids. These features include:

- Side-to-Side Motion: With its gyratory sifter motion, the GyraSift™ provides exceptional screening quality. By separating materials of varying shapes, which is typical of raw dry goods, your company can maximize its production and product quality. This could lead to gains in revenue by building your consumer base and their confidence in your items.

- High-Throughput Screening: With its large number of revolutions per minutes, our gyrasifter equipment delivers an unparalleled level of throughput screening for dry materials, such as pharmaceutical products. This feature provides your operators and facility with the ability to optimize the quality and distribution of your goods, which can help you expand your reach and revenue.

- Hook-Style Screens: Thanks to its convenient hook style screens, our GyraSift™ industrial equipment provides operators with a hassle-free method for modifying screens without imposing unnecessary downtime on your facility. This engineering feat also saves your company the cost and maintenance of maintaining multiple screen panels, which lets you maximize your uptime.

- Easy-Tension Size Support: With its innovative design, our gyrasifter equipment offers compatibility with multiple sizes of easy-tension screening media. That feature lets the GyraSift™ support a range of dry application processes, which helps your company adapt to changes with ease and boost your overall production without sacrificing quality.

With our extensive experience and customer-orientated approach, you can trust VibraScreener™ for your screening needs. If you would like to receive more information on the GyraSift™ gyratory sifter and how this unit can improve your process, please contact us today and a screening expert will contact you shortly.